|

|

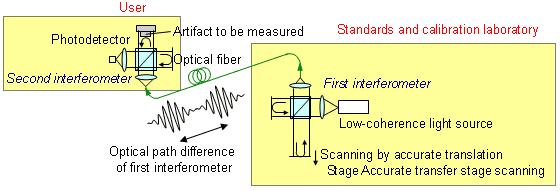

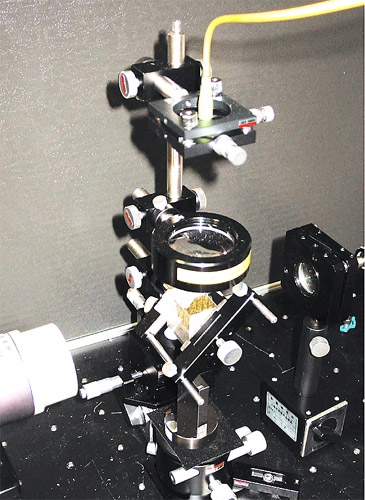

Example of remote calibration equipment

|

The Metrology Institute of Japan at the National Institute of Advanced Industrial Science and Technology (AIST) has developed a method for remote, accurate measurement of length using a tandem, low-coherence interferometer developed by the AIST and passing light signals down a 10m, single-mode optical fiber. The research has the potential for remote calibration of length standards (e.g. gauge blocks).

To date, the correction of length standards (e.g., gauge blocks) required artifacts to be sent to the Metrology Institute or standards and calibration laboratories, which risks the loss of or damage to the artifact in transit and involves shipping time there and back. Using the measuring technology developed by the AIST, the artifact can remain in situ at the user's measuring laboratory. Length values traceable to the national standard can be obtained simply by illuminating the artifact by the light through an optical fiber from a standards and calibration laboratory and detecting the reflected light with a sensor.

In the future, the research team plans to further improve the reliability of this measuring technology and aims to combine it with a wavelength stabilizing light source developed for lightwave communication zones, and then validate the remote calibration process with external organizations.

Under the Measurement Law's traceability system (Japan Calibration Service System, JCSS), The national standard of length is the iodine-stabilized He-Ne laser and length standards are currently provided using practical wavelength-stabilized lasers , length measuring instruments with optical interferometers, practical length standards such as end standards and line standards, or other devices. The gauge block end standard is the most widely used length standard in practical use. Calibration of such artifacts requires the transport of the actual gauge blocks from the user to the AIST or accredited calibration laboratories (21 companies), which risks the loss of or damage to the artifact iand involves shipping time there and back. Given that several hundred thousand block gauges require calibration each year in Japan, this transport issue needs to be addressed. Moreover, countless length measurements are performed each year and the current calibration process is at odds with today's emphasis on speed, low cost, and accuracy.

Under the Measurement Law's traceability system (Japan Calibration Service System, JCSS), The national standard of length is the iodine-stabilized He-Ne laser and length standards are currently provided using practical wavelength-stabilized lasers , length measuring instruments with optical interferometers, practical length standards such as end standards and line standards, or other devices. The gauge block end standard is the most widely used length standard in practical use. Calibration of such artifacts requires the transport of the actual gauge blocks from the user to the AIST or accredited calibration laboratories (21 companies), which risks the loss of or damage to the artifact iand involves shipping time there and back. Given that several hundred thousand block gauges require calibration each year in Japan, this transport issue needs to be addressed. Moreover, countless length measurements are performed each year and the current calibration process is at odds with today's emphasis on speed, low cost, and accuracy.

In 2001, the AIST began R&D (scheduled to run between 2001 and 2005) into Remote calibration system based on information technologies (e-trace project) on contract from the New Energy and Industrial Technology Development Organization (NEDO). This project aimed to satisfy requirements from industry side such as short turn-around time for calibration, world-widely recognized accuracy, wide area service including oversea factories, and low cost calibration fee instead of the traditional traceability system. This project selected eight examples of metrology standards from the many standards in existence, with a view to developing traceability systems based on new concepts. Research into the eight standards can be broadly divided into four areas: 1) optical fiber application, 2) electromagnetic wave frequency use, 3) Internet use, and 4) portable standards (making equipment compact and robust). The use of electromagnetic wave frequencies involves aerial transmission of frequency standards, as in GPS systems. The Internet technology involves remote calibration although not transmission of the standard artifact itself. The optical fiber method involves frequency or wavelength data incorporated in laser light transmissions (or, more accurately, optical combs and other methods).

This latest AIST research was the first of its kind in which interference signal was transmitted using an optical fiber. This research may enable the establishment of a traceability system suited to today's information society and has the potential to increase the reliability of measurements performed by general users, as well as facilitate the development of low-cost, high-speed measuring equipment and standards. The research may also have applications in household measures.