Aerosol Deposition Method: Innovative Ceramics Coating

Coating a surface with a ceramic protects various materials from friction and heat. Conventionally, high-temperature treatment was widely used for such coating, but this requires expensive equipment. The aerosol deposition method (AD method) developed by AIST enables a high-strength, high-adhesion coating to be obtained at room temperature, by simply spraying ceramic powder onto the object without having to bake it.

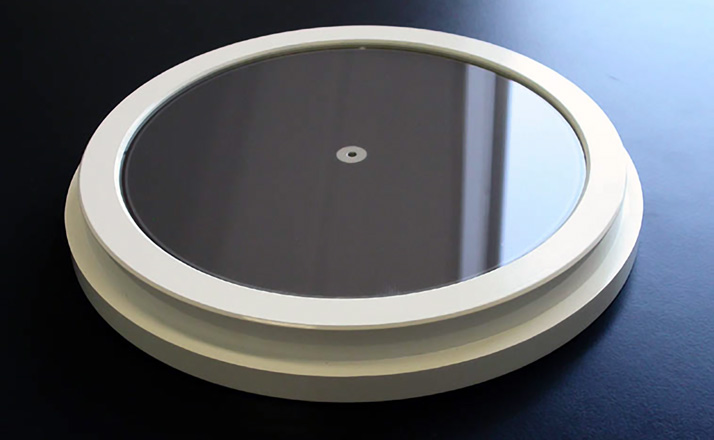

In the AD method, ceramic and metallic particles, which will form the film, of the order of around 1 µm (micrometer) or less are prepared. These are then converted to an aerosol (fine particles) by stirring and mixing with a carrier gas such as air. When they are injected from a nozzle in a decompressed container, the kinetic energy of the aerosol particles is converted to film-forming energy upon collision with the substrate. This ensures firm adhesion between the substrate and particles, and between particles. Unlike the conventional method, the coating can be carried out without the heat treatment at 1000℃ or higher, thus enabling films to be formed on ceramics, metal and plastics which are not resistant to heat. The AD method is now used for coating the parts of semiconductor manufacturing equipment, and has dramatically improved the production yield of chips, thus supporting the basis of the semiconductor industry today. In recent years, roll-to-roll manufacturing of dye-sensitization solar cell film has been successfully realized by film-forming on plastic films.