Taku Tsujimura (Leader) and Norihiko Iki of Hydrogen Energy Carrier Team, the Renewable Energy Research Center (Director: Sakae Niki), the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), in collaboration with the Institute of Fluid Science at Tohoku University (President: Susumu Satomi), have achieved 41.8 kW of gas turbine power generation using ammonia as fuel in commissioned research under the Energy Carrier project of the Cross-Ministerial Strategic Innovation Promotion (SIP) Program of the Council for Science, Technology and Innovation (management organization: Japan Science and Technology Agency (JST; President: Michiharu Nakamura)).

Ammonia has been attracting attention as a hydrogen carrier with high hydrogen content, and is particularly promising as a fuel for power generation. In the present work, the researchers were able to achieve gas turbine power generation using a methane and ammonia gas mixture, demonstrating the possibility of power generation by ammonia bifuel combustion in large-scale thermal power plants that use natural gas as fuel. They also succeeded in generating power by 100 % ammonia combustion (ammonia mono-fuel combustion), which could lead to large-scale CO2-free power generation. These results are expected to be advanced to the practical application that will contribute to significant reductions in greenhouse gas emissions in the power generation field.

Details of this technology will be presented at the NH3 Fuel Conference 2015 to be held on September 20∼23, 2015 in Illinois, USA, and at the 53rd Annual Combustion Symposium to be held on November 16∼18, 2015 in Tsukuba, Ibaraki.

|

|

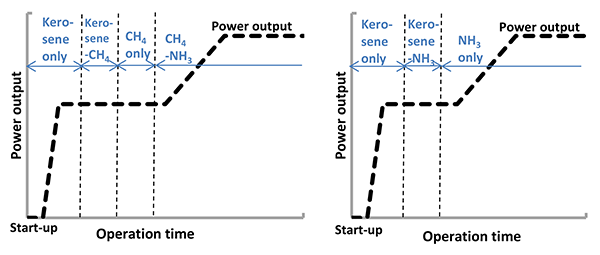

Switching of fuel feed and changes in generator output (methane-ammonia bifuel combustion (left), ammonia mono-fuel combustion (right)) |

Hydrogen energy has been attracting attention in Japan, where 2015 was declared "the year of hydrogen." In addition, with expectations higher than ever for large-scale introduction and use of renewable energy, hydrogen and hydrogen carriers are important as media for the storage and transport of energy. Hydrogen carriers are media for converting hydrogen into chemical substances containing large quantities of hydrogen to facilitate storage and transport. Hydrogen carriers include organic hydrides that are used by addition and dissociation of hydrogen to and from organic solvents (methylcyclohexane, etc.) and ammonia synthesized from nitrogen and hydrogen that is used by direct combustion.

Ammonia is gaining particular attention as a hydrogen carrier that does not contain any carbon and has a high hydrogen ratio, and expectations are high for its use as a power-generating fuel. Because ammonia generates mainly water and nitrogen upon combustion, replacing even a portion of conventional fuel with ammonia will have a large effect in reducing CO2 emissions.

AIST is promoting research and development of hydrogen carriers that support the large-scale introduction of renewable energy and is also involved in the development of technology to directly burn ammonia in a gas turbine for power generation in collaboration with the Institute of Fluid Science at Tohoku University. Ammonia faces many challenges, including its difficult ignition compared with general fuels and its slow burning velocity, and gas-turbine power generation using ammonia as fuel had not been achieved until now. However, in 2014, to illustrate the potential of ammonia as a fuel for power generation, AIST conducted demonstration tests of power generation on a gas turbine that is able to run on diverse fuels, resulting in power generation of 21 kW using combustion of bifuel where kerosene equivalent to 30 % was replaced by ammonia (AIST/JST joint press release on September 18, 2014).

Taking advantage of advances in technical development aimed at operating a gas turbine with ammonia as the main fuel, the researchers prepared facilities for feeding ammonia and methane at a high flow rate and then conducted demonstration tests of gas turbine power generation using ammonia as the main fuel. The demonstration was conducted at the Fukushima Renewable Energy Institute of AIST (Koriyama, Fukushima).

This research was carried out under the research topic "Development of Ammonia Internal Combustion Engine Technology" (Researcher: Norihiko Iki) of the "Ammonia Direct Combustion" research theme (Research Director: Hideaki Kobayashi) under the Energy Carrier project (Program Director: Shigeru Muraki) of the Cabinet Office SIP (Cross-Ministerial Strategic Innovation Promotion Program) started in fiscal year 2014.

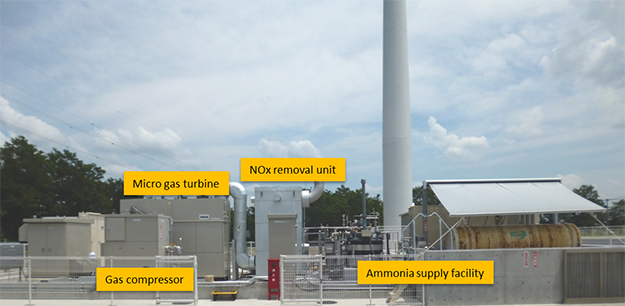

Figure 1 shows the micro gas turbine generator used in the combustion tests. Whereas the power generation equipment in 2014 included a combustor that relied on kerosene-ammonia bifuel combustion, this version of the equipment is able to stably feed both methane and ammonia gas at a high flow rate. Improvements were also made to the fuel flow control program of the gas turbine, and up to two lines of fuel, selected among kerosene, ammonia and methane, can be fed in any combination. As a result, using a 50 kW-rated gas turbine power generator, 41.8 kW of power (about 80 % of rated output) was generated by means of methane-ammonia bifuel combustion as well as ammonia mono-fuel combustion. Furthermore, the amount of nitrogen oxide (NOx) in the exhaust gas after combustion was reduced to under 10 ppm (or less than 25 ppm at 16 % oxygen (O2)), well below the Ministry of the Environment's NOx emission standards (70 ppm at 16 % O2), by adding an appropriate amount of ammonia to the exhaust gas and processing the exhaust gas in a NOx removal unit.

|

|

Figure 1: Micro gas turbine generator that can burn ammonia directly |

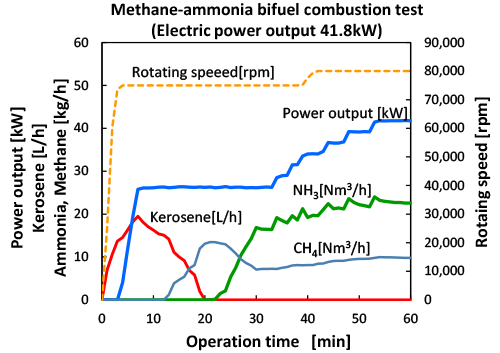

In the methane-ammonia bifuel combustion test, the gas turbine was started by feeding kerosene to the liquid fuel injection valve. After a rapid increase in rotational speed, power generation was started while maintaining the generator at 75,000 rpm. After generating 26 kW of power with the stabilized rotational speed, methane was fed to the gas fuel injection valve to carry out methane combustion and then the kerosene supply was stopped. Stable power generation was possible even after mixing in ammonia up to a volumetric flow rate ratio of 1:2.5 methane to ammonia (1:1 in calorific value). After that, while controlling the fuel supply and rotational speed, power generation output was gradually increased, and 41.8 kW was achieved at a rated rotational speed of 80,000 rpm (Fig. 2).

|

|

Figure 2: Changes in fuel feed and power generation output in the methane-ammonia bifuel combustion test |

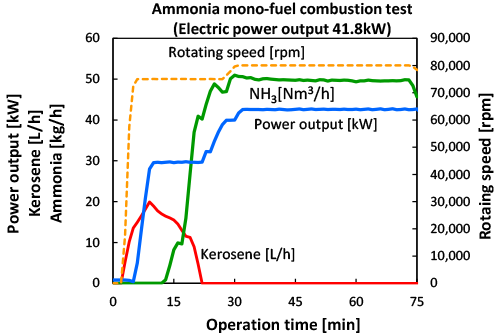

In the ammonia mono-fuel combustion test, the gas turbine was started by feeding kerosene. Then the fuel was transitioned to ammonia mono-fuel combustion by increasing the amount of ammonia. At this point, the output was checked and a power generation output of 41.8 kW was recorded at a rated rotational speed of 80,000 rpm (Fig. 3).

These test results illustrate the potential for large-scale CO2-free power generation by ammonia mono-fuel combustion or gradual introduction by replacing a portion of the fuel with ammonia at large-scale thermal power plants that use natural gas as the main fuel. The results demonstrate the potential of ammonia as a hydrogen carrier that can significantly reduce greenhouse gas emissions.

|

|

Figure 3: Changes in fuel feed and power generation output in the ammonia mono-fuel combustion test |

In both tests, it was possible to reduce NOx emissions to less than 10 ppm by adding an appropriate amount of ammonia to the post-combustion exhaust gas and processing the NOx in a NOx removal unit. In the case of the ammonia mono-fuel combustion, although there was residual unburned ammonia at 11 ppm, none was detected downstream of the NOx removal unit. In the case of the methane-ammonia bifuel combustion, there was no residual unburned ammonia, indicatating that under the same power generation conditions the methane-ammonia bifuel combustion is more powerful than ammonia mono-fuel combustion.

The researchers plan to more closely examine the characteristics of methane-ammonia bifuel combustion and ammonia mono-fuel combustion in gas turbines, to acquire knowledge that will lead to the realization of improved combustion and low-NOx combustion as well as practical ammonia power generation systems, and to continue to demonstrate the technology.