The Quantum Electrical Standards Group of the Research Institute for Physical Measurement (Director: Yasuhiro Nakamura) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi), in collaboration with ADC Corporation (ADC; President: Hiroshi Mochida), has developed a compact direct current (DC) voltage standard with the world’s highest level of performance in temporal stability and temperature stability.

The developed DC voltage standard was achieved by employing a quantum standard for precise measurement of the voltage standard unit that serves as a reference standard and by utilizing circuit noise countermeasures, heat insulating packaging, and a modularization technology. High-precision voltage measurement becomes possible at R&D and quality management departments of manufacturers, universities, research institutions, and calibration facilities, and the efficiency of calibration operations is expected to improve dramatically.

|

|

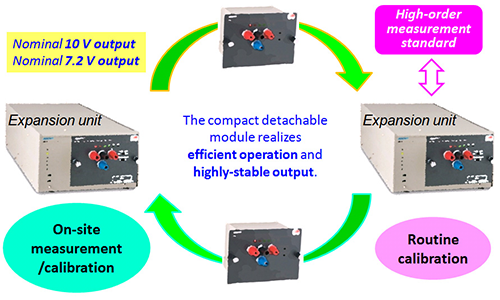

The developed DC voltage standard and illustration of its use |

In the manufacture of electronics, high-precision measuring devices are required for accurately measuring electrical quantities. In addition, the DC voltage standard for testing and calibrating the precision of measuring devices is extremely important for maintaining and managing the high precision of those measuring devices.

Currently, the voltage standard of Japan is maintained and managed using a Josephson effect voltage standard, which utilizes superconductive technology, and the standard is provided to users (calibration facilities) via limited models of large DC voltage standards.

In recent years, electricity-based control and drive methods are being used in many products and their manufacture, making voltage measurement more important than ever at the manufacturing sites. Therefore, a compact DC voltage standard capable of accurate and sophisticated voltage measurements regardless of location is desirable.

As the national metrology institute of Japan, AIST has pursued the development of the highest level of national measurement standards throughout the world and the establishment of the traceability system needed by the industrial sector. In the field of DC voltage, AIST has early realized a Josephson effect voltage standard based on quantum-mechanical principles, and has been improving and studying the standard. AIST has also been developing precise voltage standard measurement techniques.

ADC has been working to develop measurement devices for electrical properties, such as the digital multimeter, and to improve their precision and functions. However conventional instruments that use semiconductor technology had limitations with respect to the precise evaluation of the temporal stability of standard source modules of voltage, which is an important key to determining the performance of those devices.

Therefore, the precise measurement technology of AIST, which uses the Josephson effect voltage standard, was combined with ADC’s packaging technology for voltage standard modules in order to develop and evaluate an original DC voltage standard and to achieve the maximum level of stability.

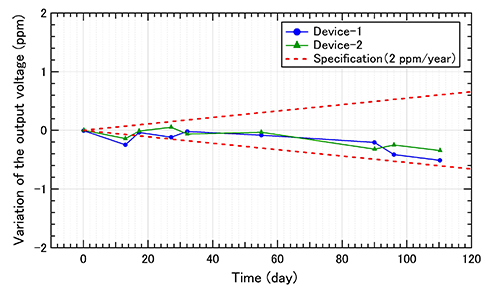

In this research, the temporal change properties of the Zener diode elements required for the DC voltage standard were evaluated using the Josephson effect voltage standard (figure). The multiple evaluation results were used to select elements with good properties, and after the selected elements were installed in a module for temperature control, evaluation, improvement, etc. of the temperature coefficient were carried out. The developed DC voltage standard has the world’s highest level performance as a compact DC voltage standard. The output voltages of the developed standard were 7.2 V and 10 V. Excellent performance was achieved at both outputs: at a 7.2-V output, the temporal stability was ±1 ppm (1 in 1 million)/year, and the temperature stability was ±0.02 ppm (2 in 100 million)/°C; and at a 10-V output, the temporal stability was ± 2 ppm (2 in 1 million)/year, and the temperature stability was ±0.03 ppm (3 in 100 million)/°C. This is equivalent to or better performance than that of the currently sold, top-rated DC voltage standards, which have a temporal stability of ±2 ppm/year and a temperature stability of ±0.04 ppm/°C at an output of 10 V.

The major issue with the conventional standards is that once the power is turned off, a considerable amount of time (several tens hours) is required after turning it back on until the standard can be stably used again. In addition, because the most recent calibrated value cannot be guaranteed after the power to the standard is turned off, calibrations must be repeated when high-precision traceability is required.

The developed DC voltage standard was thus created to have the configuration of a compact detachable module (main unit) and multiple expansion units (battery packs) to allow the standard to be used for 40 hours or longer without turning off the power. When the main unit is mounted to the expansion pack, the standard voltage output is obtained for an extended period of time by battery power, without a connection to an AC power supply, enabling accurate measurements without superimposed noise from the AC power supply. The main unit was also greatly miniaturized over conventional DC voltage standards, and has a built-in battery that enables it to maintain the power supply for a period of 20 minutes. Thus, if expansion units are prepared at each required location, it is possible to move only the main unit from one location to a different location while maintaining the power supply. The main unit can be removed from one expansion unit and inserted into a separately prepared expansion unit enabling continuous calibration operations, with this capability expected to greatly improve operation efficiency.

|

|

Figure: Example of evaluation data for the elements (single units) used for the DC voltage standard |

AIST and ADC intend to continue providing their collaboratively developed DC voltage standard for use as a voltage standard for measurement devices such as high-precision digital multimeters and voltage/current generators.