- Highly sensitive detection of biological substances with simple mechanism and easy operation -

Makoto Fujimaki (Leader), Optical Sensing Group, the Electronics and Photonics Research Institute (Director: Satoshi Haraichi) of the National Institute of Advanced Industrial Science and Technology (AIST; President: Ryoji Chubachi) and Ken-ichi Nomura (Researcher) and Nobuko Fukuda (Senior Researcher), Advanced Surface Processing Team, the Flexible Electronics Research Center (Director: Toshihide Kamata) of AIST, have developed a V-shaped cross section microfluidic channel type sensor (V-trench biosensor). The V-trench biosensor can detect target biological substances with high sensitivity using surface plasmon resonance field enhanced fluorescence (SPRF) to enhance light signals emitted from fluorescent tags attached to the target biological substances.

By forming the cross section of microfluidic channel into a V-shape, the fluidic channel has been integrated with the optical prism and the surface plasmon resonance (SPR) excitation layer that are required to manifest SPRF function. Furthermore, with the sensor optical system aligned in a straight line, a biosensor system with both the high sensitivity of SPRF and the easy operability of a microfluidic channel has been realized. Quantitative detection of trace amounts of biomarkers and viruses in the body can be conducted with minute samples, as small as several μl, and in addition to enabling more accurate diagnosis at clinical sites, it is expected to contribute as a biosensor system for daily health management.

Part of the results of this research has been obtained under a commissioned project by the New Energy and Industrial Technology Development Organization (NEDO).

Details of the results will be published in the British scientific journal "Nature Communications" on December 12, 2013 (British time).

|

|

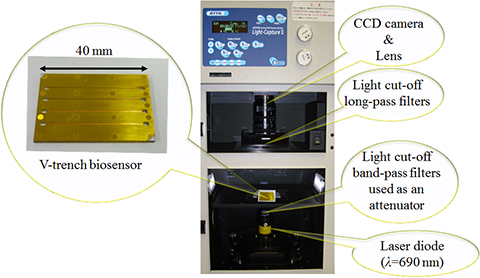

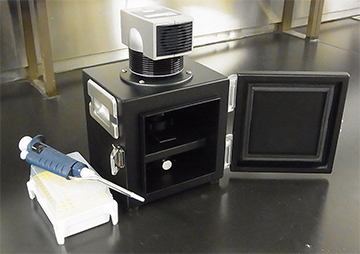

V-trench biosensor chip (left) and the fluorescent light detection system for the V-trench biosensor based on a commercial product (right) |

In recent years, various biomarkers that are produced inside the body from various diseases are being identified making it possible to detect early onset of cancers and lifestyle-related disease such as diabetes. In addition, it is now being found that the detection of these biomarkers can be used to detect diseases that have not become manifest (pre-illness state), a condition in which the person is not yet ill but is going to fall ill. Attention is being given to this as a technology to prevent people from falling ill. Furthermore, if trace amounts of bacteria or viruses can be detected quickly with high sensitivity at a very early stage, then faster recovery can be expected by starting initial treatment earlier, as well as preventing infectious diseases from spreading.

The key technology to achieve this is ultra-high-sensitivity biosensor technology. Many sensor technologies have already been commercialized however, they still face the problems of insufficient sensitivity and quantitative performance under simplified testing. On the other hand, operation of high sensitivity detection methods is complex and quick on-site judgment is difficult. Currently, there is no on-site technology to diagnose a pre-illness state or early-stage infection accurately and research is being conducted under various approaches towards its achievement, in the forms of improvements in conventional technology and developments of new technology.

AIST conducted an in-house research project titled "The development of a multi-marker measurement system for early diagnosis of lifestyle-related diseases" (Project leader: Yasukazu Yoshida, Director, Health Research Institute) in FY2010 and 2011 targeted at prevention and early diagnosis of lifestyle-related disease such as diabetes which now account for 30% or more of national health care costs. By integrating technologies dispersed among the various research units of AIST, AIST developed a group of biomarkers (multi-markers) to diagnose pre-illness state as well as a system to measure and evaluate these multi-markers quickly at the same time. The V-trench biosensor is a sensor technology conceived and developed in this project. Since then, the Electronics and Photonics Research Institute of AIST has continued to make improvements to this technology, has optimized the V-trench shape, and improved surface modification methods. The Institute has succeeded in detecting DNA and the influenza virus using antibodies.

A feasibility study to apply this technology for the development of avian influenza monitoring system is currently underway in collaboration with Panasonic Corporation and Kobe University, under the commissioned project "Project to Develop Sensor Systems to Address Social Issues, ([4] Feasibility study of R&D results in other areas, FY 2013)" of NEDO.

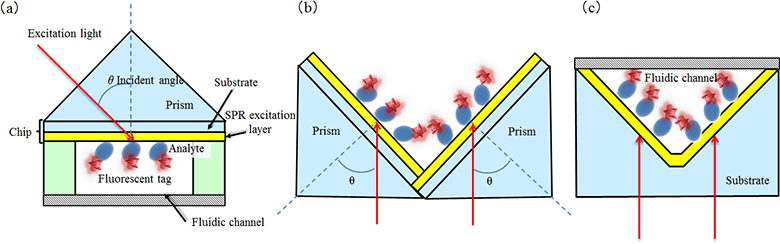

The conventional SPRF detection system was structured with a channel to contain the sample bonded on top of a chip with a SPR excitation layer affixed to an optical prism. It was also necessary to adjust the incident angle of the excitation light to a set angle against the prism (Fig. 1(a)). This resulted in poor usability and large equipment dimensions, and although its high sensitivity was acknowledged, it was not put into practical use. To overcome these issues, a V-shaped microfluidic channel structure as shown in Fig. 1 (b) and (c) was conceived. The bottom of the microfluidic channel serves as the light incident surface of prism and the channel itself has the prism functionality, and the inner surface of the channel is coated with a thin gold (Au) film to form the SPR excitation layer. This has enabled the prism, detection chip, and fluidic channel that were separated into three units to be combined into a single setup. The vertex angle of the V-trench has been set so that when excitation light enters the bottom of the sensor chip perpendicularly, it will excite the SPR. This removes the need of cumbersome adjustment of the incidence angle, and thereby enables SPRF effects to be obtained merely by placing the chip horizontally against the excitation light being projected from below.

|

Figure 1 : (a) Conventional optical system for SPRF excitation

Detection chip affixed to the bottom of the prism; fluidic channel bonded to the surface of the detection chip for measurement.

(b) Conceptual diagram of V-trench biosensor combining two conventional prisms to be rotated and assembled, at the time of its conception

(c) Cross section of the developed V-trench biosensor chip |

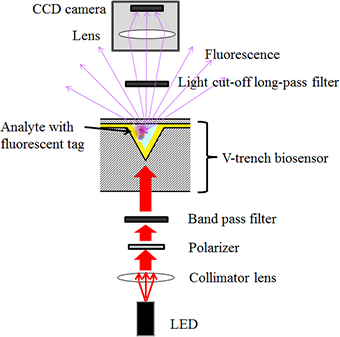

The overall configuration of the sensor system is shown in Fig. 2. LED is used as a light source in the shown case. After conditioning the light from LED into parallel light using a collimator lens, it is polarized to the orientation required for SPR excitation using a polarizer. The light then passes through a band pass filter to near it to monochromatic light and is projected perpendicularly to the bottom of the V-trench biosensor. Laser diodes (LD) can also be used as a light source. As its light is almost monochromatic and polarized, the polarizer and band pass filter will be unnecessary if LD is used. SPR will be excited on the Au thin film surface formed on the inner surface of the V-trench by the excitation light. When a biological substance labeled by fluorescent dye is adsorbed by this surface, it will emit a strong fluorescent light, which enables high-sensitivity detection of the biological substance. Polystyrene was used as the material for the sensor chip. The optimum value for the vertex angle has been calculated to be 49° from the wave length of excitation light and the refractive index and the thickness of each material. The long pass filter in Fig. 2 is installed to allow only the fluorescent light to pass through while preventing the excitation light from directly entering the CCD camera.

|

|

Figure 2 : Overall diagram of a V-trench biosensor system |

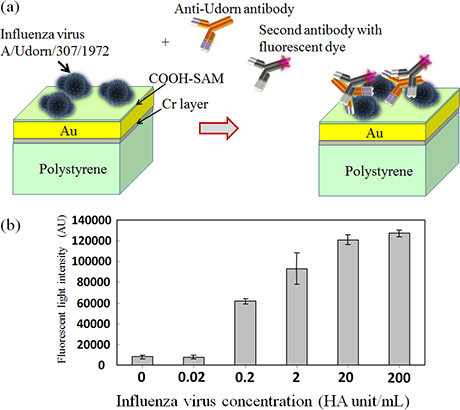

Figure 3 shows the results of influenza virus detection. For the sensor used in this case, an Au layer was formed as the SPR excitation layer on top of a 0.6 nm chrome (Cr) adhesive layer on the inner surface of the V-trench. A carboxylic terminated (-COOH) self-assembled monolayer (SAM) was formed on the Au layer. The A/Udorn/307/1971 virus, a type A influenza virus, was immobilized on the monolayer surface. After blocking with ethanolamine, an anti-Udorn antibody was added, and then an antibody labeled with fluorescent dye Alexa-Fluor-700 was added as a secondary antibody. Figure 3 (b) indicates the relationship between the influenza virus concentration and the fluorescent light intensity. The measurement time was set at 2 minutes. As indicated in the figure, a 0.2 HA unit/ml concentration virus was detected with significance against the noise level. In addition to the detection of the influenza virus, it was possible to detect DNA at a concentration of 1 nM (M = mol/l) and 100 fM for the biotin-streptavidin bond.

|

Figure 3 : (a) Schematic diagram of the reaction taking place at the chip surface when the influenza virus was detected using the V-trench biosensor

(b) Relationship between influenza virus concentration and fluorescent light intensity |

At this point, the signal strength obtained from the V-trench biosensor is 1% or less of its theoretical value. This is believed to be caused mainly by the wavy roughness of the V-trench surface. The sensor chip is formed using a metal die, and the metal die has a convex triangular shape corresponding to the V-trench. The metal die had an undulation with a pitch of several tens of micrometers and a height of several hundred nanometers remaining even after polishing, and this is reflected on the inner surface of the V-trench. This undulation is believed to be the cause of SPR not being excited as predicted by the theory, and lowering the sensitivity. Improving the precision of the metal die can be expected to enhance sensitivity by at least one or two orders of magnitude.

A V-trench biosensor system for an avian influenza virus monitoring system was prototyped in collaboration with Panasonic Corporation and Kobe University using the developed technology, as a commissioned project of NEDO (Fig. 4). Compared to the prototype biosensor system made under AIST's in-house project conducted in FY2010 and FY2011 (L × W × D: 630 × 320 × 345 mm) the new prototype biosensor system has been greatly downsized to about one-ninth in volume, measuring only 260 × 180 × 160 mm. The new prototype system adopts a cooled CCD for its fluorescent light detection unit, but if this unit can be replaced by a photo diode, it is possible to further downsize and lighten the system.

|

|

Figure 4 : V-trench biosensor system prototyped in November 2013 under the NEDO commissioned project |

The V-trench biosensor is able to detect substances of the 100 fM order, depending on the detection target and has achieved satisfactory sensitivity in the detection of many biomarkers. However, in order to detect trace amount of viruses existing in the environment (for example, inside a room) before human beings are infected, it is estimated that enhancement of sensitivity by three orders of magnitude from the current level is necessary. Aiming at the high sensitivity to respond to these needs, the sensor manufacturing process will be improved to achieve a more ideally shaped V-trench and the technology to concentrate a target substance inside the V-trench will be applied. In addition, liquid samples are currently injected manually using a pipette. Another goal will be to combine the system with microfluidic channel liquid transfer technology and equip it with a small pump to establish a system that makes detection even easier. The target is to commercialize it as a laboratory level trace substance sensing system in two to three years, while aiming at producing a system within several years that can be used at clinical sites.