Point

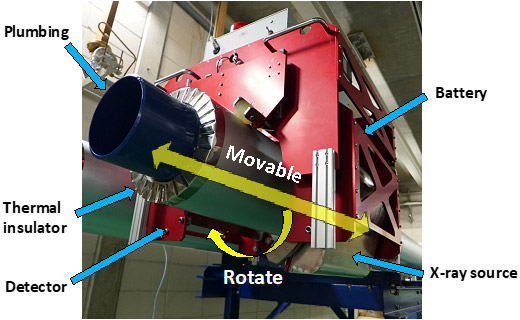

The researchers have developed a small-sized, light-weight, battery-drive, X-ray non-destructive inspection apparatus that has enough ability for inspection, and can be mounted on a movable robot.

Figure 1. X-ray source unit mounted on a plumbing inspection robot |

|

Figure 2. X-ray transmission image of lead—letters through steel plates (5cm thick)

|

New Results

The developed X-ray non-destructive inspection apparatus mainly consists of a compact, high-energy X-ray source using a carbon nanostructure for an electron emitter, and a highly sensitive X-ray detector. The apparatus is capable of taking an X-ray transmission image through a 5-cm thick steel plate with one 0.1-second X-ray pulse, and also has enough ability of taking an X-ray transmission image of a reduction in thickness of 6-inch plumbing with multiple X-ray pulses. In addition, the system does not require to be plugged into power supply and all the components in the apparatus can be driven by a small-sized light-weight battery. As a result, efficient, non-destructive inspections can be performed with a remote-controlled infrastructure X-ray inspection robot.

Background

In recent years, aging infrastructures have become social issue. X-ray non-destructive inspection is a powerful technique to inspect infrastructures. However, in order to inspect efficiently using a robot, a small-sized and light-weight X-ray inspection system which is mountable on a robot, and at the same time, the X-ray inspection system is desired to have enough ability for industrial use.

Future Plans and Applicability

In the future, the researchers will perform demonstrative experiments, such as a chemical plant piping inspection, as well as examinations of applications to non-destructive infrastructure inspection, thus will contribute to achievement of a safe and secure society by reducing accident frequency due to aging.